By Jeremiah E. Josey, founder of IPRI.Tech

29 November 2024

1 Introduction

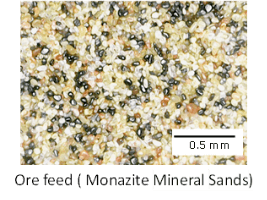

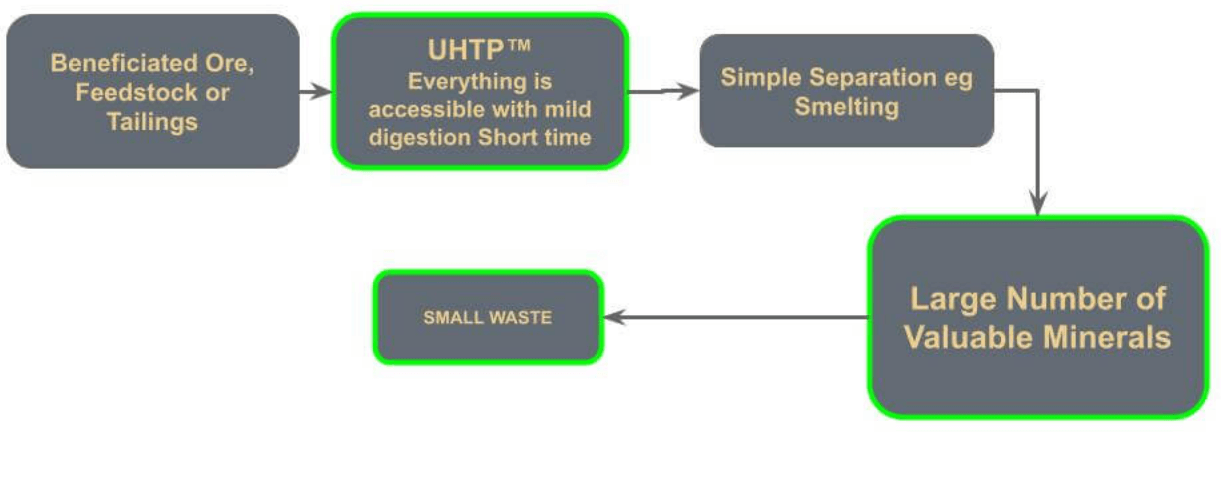

IPRI.Tech has developed a plasma-based pre-treatment process for REE bearing particulate ores that promotes REE recovery and improves the control of radioactive components (Naturally Occurring Radioactive Materials (NORMs)). The IPRI process utilises high temperature (~10,000ºC) plasma to dissociate REE bearing minerals into their most basic components, allowing chemical recombination into mineral species that respond more favourably to chemical leaching. The high temperature dissociation transforms naturally occurring halide, carbonate, phosphate or silicate REE ores into oxides, which are more amenable to recovery and have chemical behaviour that allows better control of NORMs. IPRI refers to REE ores that have undergone the plasma pre-treatment dissociation process as Plasma Treated Mineral, or “PTM.”

Studies have shown that despite relatively higher energy consumption of plasma treatment, the IPRI process is technically and financially viable due to significant downstream savings linked to reduced heating and chemical needs when recovering REE from Plasma Treated Mineral. IPRI leverages proprietary intellectual property and world-class expertise in plasma treatment of REE, mineral processing innovation, and geometallurgy, supported by over 40 years’ experience in these areas.

2 Explanation of the Plasma Treatment Process

Plasma pre-treatment modifies mineral structure via high temperature, driving physio-chemical transformation that improves chemical leachability. The material is fed through plasma exceeding ~8,000ºC, where its physical and chemical structure breaks down into elemental components. For typical phosphate Rare Earth (RE) ore:

RE.PO4→RE+P+4O

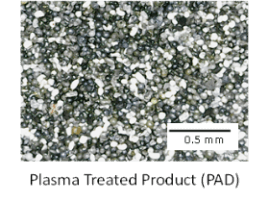

The Rare Earth Phosphor Oxygen molecular species separates into Rare Earth, Phosphor, and Oxygen elements. Exiting the plasma, these free elemental species recombine to generate Plasma Treated Mineral (PTM), mostly oxides as oxygen is highly reactive. Rare earth phosphates are thus transformed into rare earth oxides; radioactive species form NORM oxides such as thorium or uranium oxides.

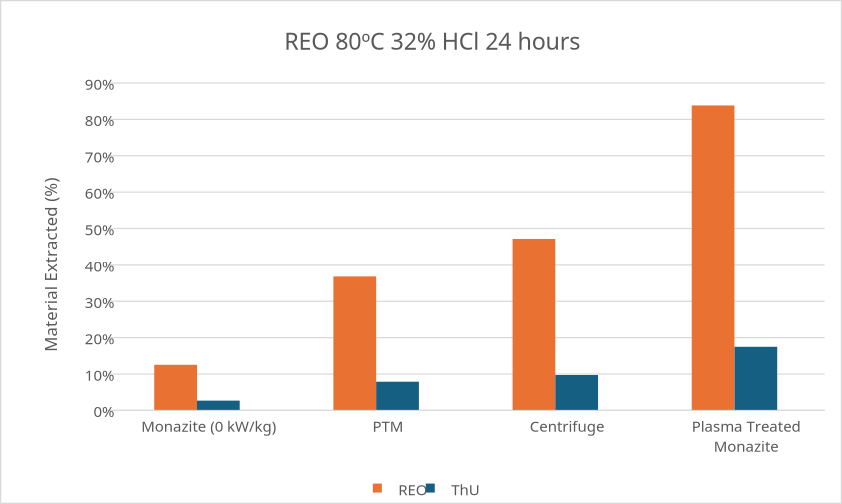

Successful commercial trials demonstrate that rare earth and radioactive oxides are loosely intermixed in PTM and often physically connected within PTM particulates. The phosphor (II) oxides form a separate physical by-product. Separation of radioactive species such as thorium and uranium oxides (NORM oxides) from PTM is achieved using light acid leaching that dissolves rare earth oxides but not NORM oxides. Tested acids include phosphoric, hydrochloric, and nitric acids, with results varying by ore.

Multiple valuable by-products have been identified, including phosphoric acid and spherical iron, adding financial benefits.

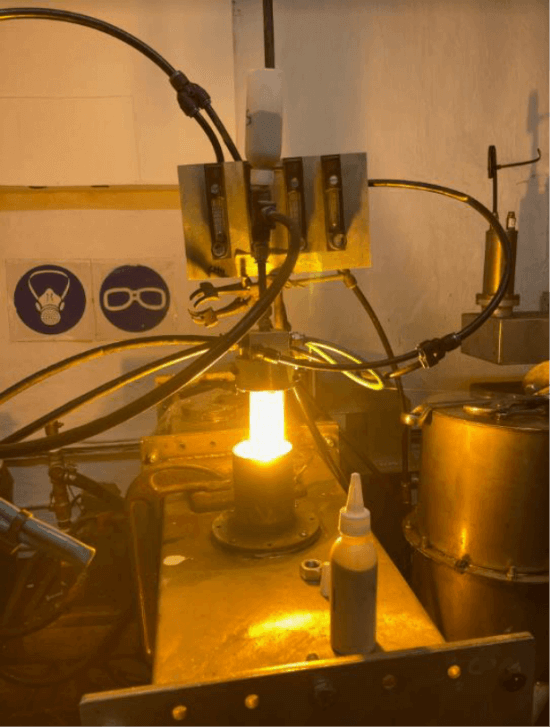

In the IPRI-developed process, REE ore particles require a short plasma exposure (<1 second) to reach dissociation temperature. The pilot-scale plasma rig uses gravity-fed material falling through the plasma chamber, with treated PTM collected at the chamber bottom. The enclosed plasma system employs a semi-batch approach.

3 Technical Details

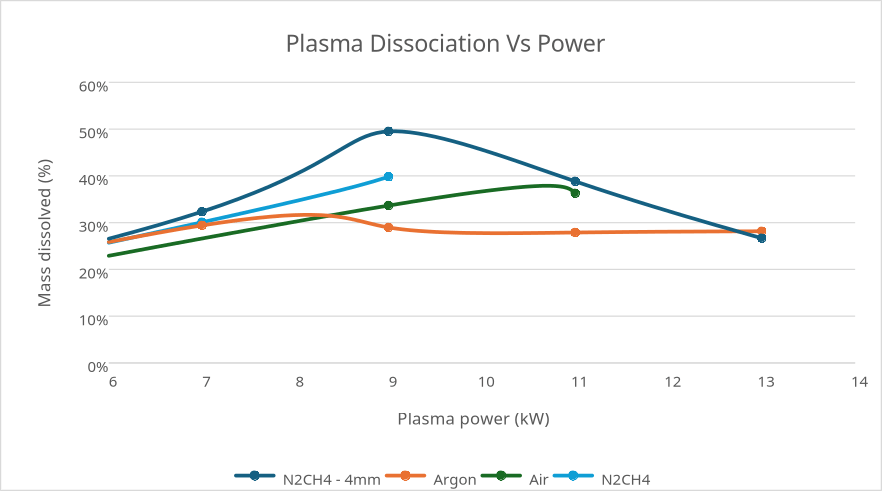

IPRI’s plasma reactors employ high-frequency RF power (range 10 kHz to 15 kHz) generating high-purity plasma in low-pressure (~50 Pa) enclosed chambers with precise control of temperature, proprietary gas composition (argon, oxygen, nitrogen), and flow rates (0.1-1 NL/min). This enables programmed multi-step operations optimising mineral dissociation and oxidation states.

The uniform gas distribution and controlled vacuum environment facilitate rapid mineral breakdown and surface activation. Particle dissociation proceeds with consistent thermal exposure, yielding PTM with enhanced surface area and reactivity.

4 Advantages of IPRI Plasma Technology

- Improved REE recovery and NORM control.

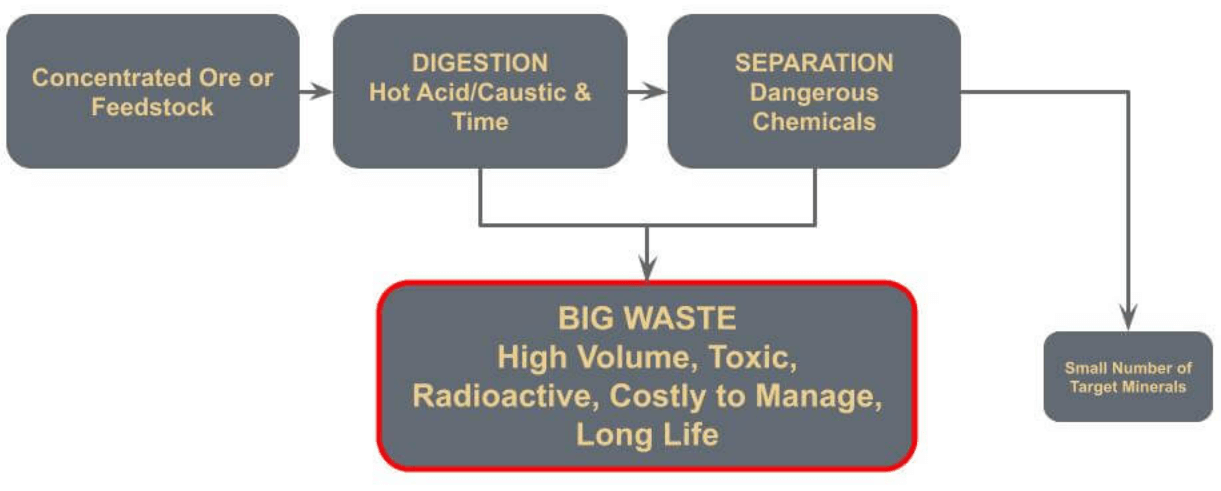

- Reduction of hazardous chemical use by 40 to 80% during leaching, leveraging milder, room-temperature acid treatments.

- Elimination of NaOH roasting, shortening and simplifying the processing chain.

- Recovery of multiple by-products such as phosphoric acid and metallic iron spheres.

- Lower overall capital and operational expenses despite high plasma energy use, balanced by savings in heating and chemical consumption.

- Modular, scalable systems adept for smaller operations and ore-specific tuning.

- Environmental sustainability due to chemical-free, low emission processing.

5 Conclusion

IPRI’s plasma-assisted digestion technology represents a mature, industrially proven approach to REE recovery, combining innovative Ultra High Temperature Pyrometallurgical™ (UHTP™) techniques with precise plasma control. By transforming complex REE ores into plasma treated minerals (PTM), IPRI enables enhanced chemical leaching efficiency, superior NORM control, and valuable by-product generation. These advantages position IPRI’s technology for commercial success and broader adoption in sustainable mineral processing.

6 Glossary

Acid Leaching

A chemical process to extract metals from ores by dissolving them in acidic solutions, commonly used to recover rare earth elements (REEs).

Elemental Components

The most basic chemical constituents (elements) into which a compound or mineral is broken down during plasma dissociation.

Leach Heating Costs

Energy expenses related to heating leaching solutions during mineral extraction processes.

Light Acid

A dilute acid used in selective leaching to dissolve certain mineral oxides (e.g., rare earth oxides) without dissolving others (e.g., radioactive NORM oxides).

Mineral Processing

The industrial process of separating valuable minerals from their ores.

NORM (Naturally Occurring Radioactive Materials)

Radioactive substances naturally present in mineral ores, including thorium and uranium oxides, requiring special handling and control during mineral processing.

Oxides

Chemical compounds containing oxygen and at least one other element; in this context, oxides formed from rare earth elements during plasma pre-treatment.

Particulate Ores

Ores composed of fine particles, which can be processed by plasma treatment to enhance mineral recovery.

Plasma

An ionized gas containing energetic electrons, ions, and neutral particles capable of inducing physical and chemical changes in materials exposed to it.

Plasma Assisted Digestion™ (PAD™)

IPRI’s proprietary process using ultra high-temperature plasma to dissociate minerals into more reactive oxides, improving extraction efficiency.

Plasma Pre-treatment

Use of plasma to modify the physical and chemical structure of minerals before chemical leaching.

Plasma Treated Mineral (PTM)

Mineral materials that have undergone plasma pre-treatment, resulting primarily in oxide forms more amenable to leaching.

Semi-batch Process

A processing approach where material is added in portions over time to the plasma treatment system, rather than continuous feeding.

Ultra High Temperature Pyrometallurgical™ (UHTP™) Technology

IPRI’s trademarked plasma processing technology operating at ~10,000ºC for mineral dissociation and recovery enhancement.

7 References

- International Plasma Research Institute. “Welcome to the International Plasma Research Institute™.” IPRI.Tech Website. Accessed November 2024.

URL: https://ipri.tech - IPRI.Tech LinkedIn Page. “IPRI.Tech Company Profile.” LinkedIn. Accessed November 2024.

URL: https://ch.linkedin.com/company/ipri-tech - Smith, J., et al. “High-temperature plasma processing for rare earth element extraction.” Nature Communications, 2024.

URL: https://www.nature.com/articles/s41467-024-53684-6 - Lee, A., & Nguyen, P. “Plasma treatment effects on REE ores: Chemical transformation and recovery.” Chemical Engineering Science, 2024.

URL: https://www.sciencedirect.com/science/article/abs/pii/S0883292724002634 - IPRI.Tech. “Our Advanced Mineral Processing Services.” IPRI.Tech Service Page, 2024.

URL: https://ipri.tech/services/ - Lawrence Livermore National Laboratory. “Advancing Rare Earth Biomining for Secure Supply.” Lawrence Livermore National Laboratory Science & Technology Review, April-May 2024.

URL: https://str.llnl.gov/past-issues/aprilmay-2024/advancing-rare-earth-biomining-secure-supply - Zhao, B., et al. “Innovations in plasma-assisted digestion for mineral processing.” Journal of Cleaner Production, 2024.

URL: https://www.sciencedirect.com/science/article/abs/pii/S1002072124000358